Short Answer: Use water, salt water, bentonite, calcium chloride, foil pits, or all of the above where the ground contacts your electrodes. Try to get less than 5,000 ohms for contact resistance.

Long Answer: There are a few simple ways that you can improve contact resistance for surface and/or borehole survey lines. Most of the solutions below are interchangeable, however, we have also noted what conditions need a particular solution.

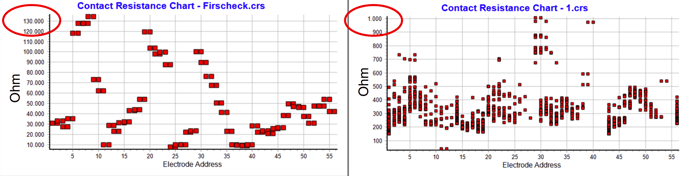

Tip: If you're using a SuperSting™ Wifi, it can check the contact resistance for each electrode before you start your survey.

Firstly, always try to get the lowest contact resistance possible. Shoot for <5,000 ohms in general—though we often recommend trying to get <1,800 ohms if possible as this allows SuperSting™ to use the full 200 watts in Boost Mode. Read more in this article.

For General Purposes:

- Salt Water or Regular Water: For most purposes, soaking the ground underneath your stainless steel stakes with salt water will work to improve contact resistance. A 2% saline solution should work fine. If salt water is not available, non-saline water can also work.

- Bentonite or Bentonite Slurry: Bentonite clay can be poured and spread near you stakes/borehole in order to improve contact resistance. You can also opt to mix Bentonite with Salt Water to make a slurry.

- Calcium Chloride: Similar to Bentonite, you can use a mix of Calcium Chloride (CaCl2) with water. Be careful with this mix, however—since CaCl2 and H2O create heat when mixed.

- Foil Pits: Sheets of standard aluminum foil can be used. Dig a small hole where your electrode will be. Simply tear a few small sheets of foil and place where your stainless steel stake will be hammered. Then, impale the sheets with your stake when hammering into the ground to create a foil pit. Cover the pit with loose dirt.

- Some or All of the Above: Though not completely necessary, you can mix and match some of the above methods. As mentioned, you can mix bentonite and salt water. You can also soak the ground underneath your foil pit with salt water or bentonite—and then add more salt water on top of the foil.

For Hot, Arid, or Sandy Areas:

- Bentonite or Bentonite Slurry: Bentonite clay or slurry (bentonite/salt water mix) will not evaporate as easily as saltwater alone, making it an ideal method for hot areas. It can be poured and spread near your stakes/borehole in order to improve contact resistance.

- Calcium Chloride: Similar to Bentonite, you can use a mix of Calcium Chloride (CaCl2) with water for hot areas. This mix will generate heat so be mindful.

- Foil Pits: Sheets of standard aluminum foil are another ideal solution in hot areas. Dig a small hole where your electrode will be. Simply tear a few small sheets of foil and place where your stainless steel stake will be hammered. Then, impale the sheets with your stake when hammering into the ground to create a foil pit. You can also cover the pit with loose dirt/sand. If you are also getting IP measurements then avoid using foil pits due to polarization effects on the IP measurements.

- Install Electrodes a Day in Advance: Sometimes in dry/sandy areas, if the electrode positions are prepared in advance—say, by a day or two—you will get excellent contact. This gives the ground time to shift and fill in gaps around your electrode.

- Some or All of the Above: For really hot and arid areas, you may want to pour Bentonite or Calcium Chloride (CaCl2) Slurry and use Foil Pits to be safe.

For Gravely or Rocky Areas:

- Bentonite, Bentonite Slurry: Bentonite clay or slurry is ideal because it has the benefit of filling in some of the gaps created by gravel or loose rocks. Because it is thicker than water, the slurry keeps the liquid from draining away into the porous ground. It can be poured and spread near your stakes/borehole in order to improve contact resistance.

- Tip: If you're placing the electrode directly onto rock (such as in a quarry), you can use bentonite along with a rubber band to keep the electrode in place.

- Calcium Chloride: Similar to Bentonite, you can use a mix of Calcium Chloride (CaCl2) with water for hot areas. This mix will generate heat so be mindful.

Example of using water & a foil pit:

Example of how something like medical gel can reduce contact resistance: